About Us

Discover our Constant Challenges and Growth History. We have been Technological Leaders in In-line Scanning for over 40 Years.

Home » About Us

WHO WE ARE

The Origins of BIOMETiC

Our history begins in March 1980. Among the South Tyrolean apple orchards, our President and Founder Federico Giudiceandrea and his two friends, Paul Durst and Hansjörg Thaler, developed the first automatic calibration tool on the market for distinguishing red apples from yellow ones.

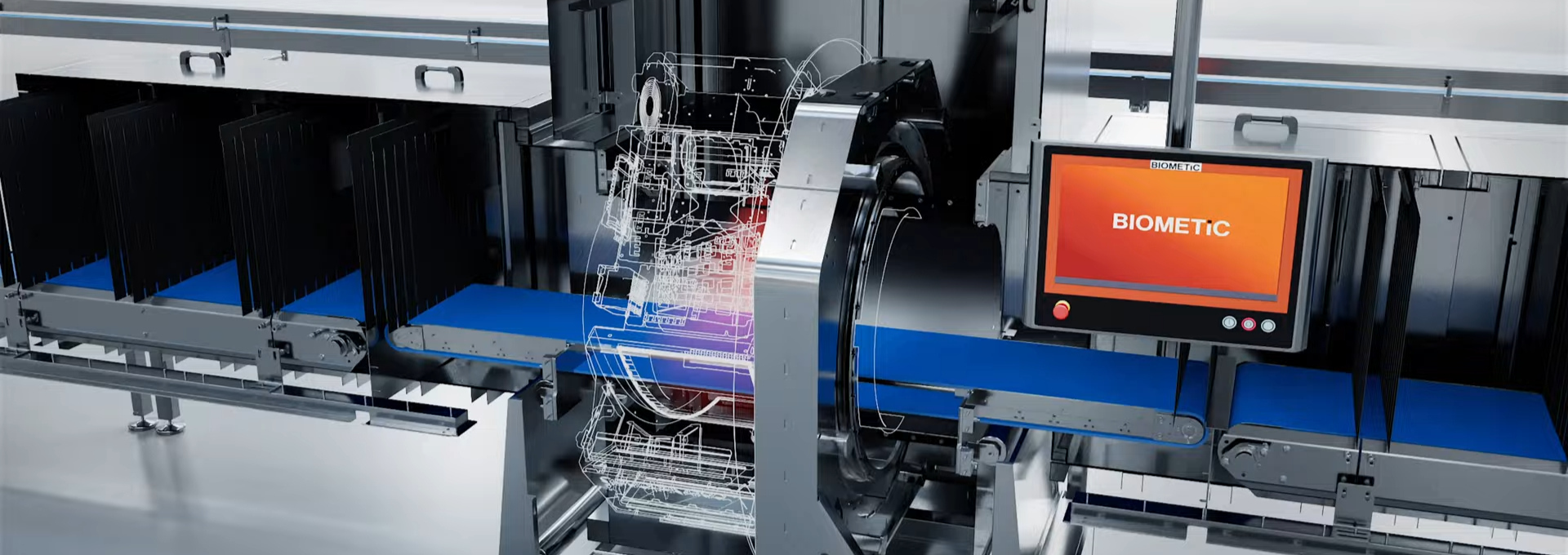

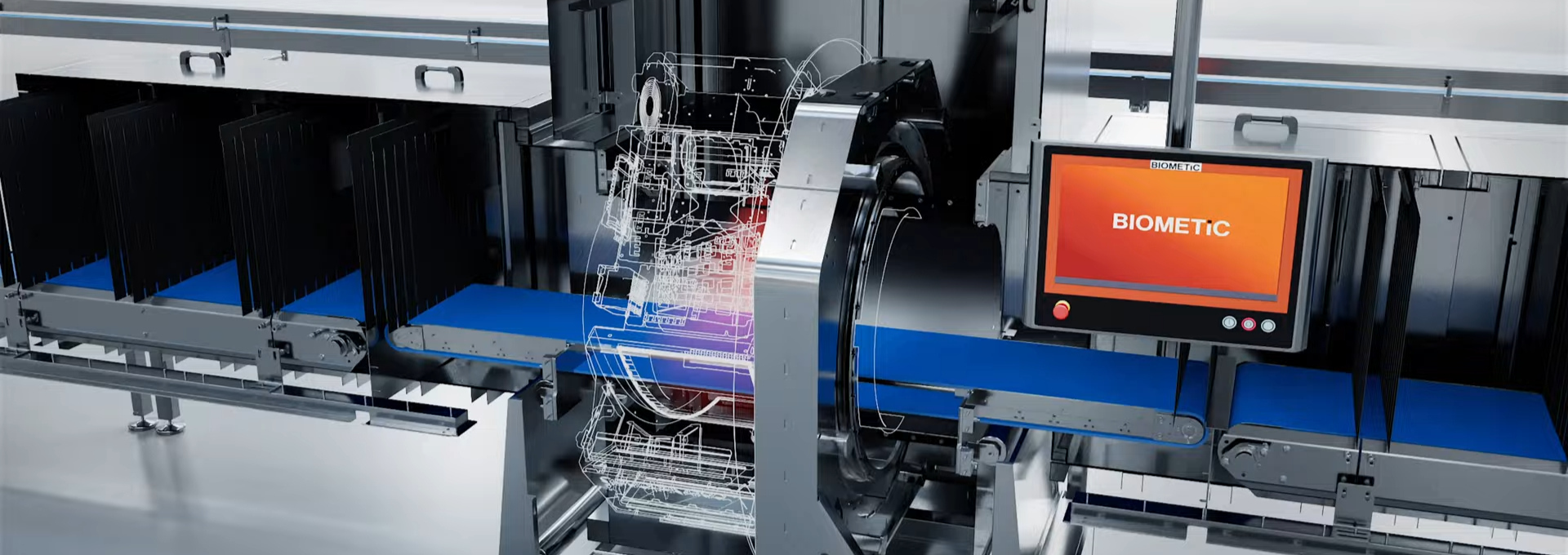

BIOMETiC is founded in 2012 as part of the MiCROTEC Group, the leading global provider of measurement systems and automated process development for the wood industry. The technology of quality solutions that MiCROTEC uses for wood scanning has been adapted to food scanning. BIOMETiC thus benefits from MiCROTEC’s over 45 years of experience and know-how in the field of innovative in-line biometric scanners and high-speed process optimization.

BIOMETiC offers innovative tools and solutions based on advanced technologies, for the automation and optimization of production processes in the food industry that increase the added value of the final product. Our primary objective is to ensure the success and satisfaction of its customers in order to guarantee to the final consumer a safe and high-quality product.

OUR HISTORY OF TECHNOLOGICAL INNOVATIONS FOR THE FRUIT AND FOOD INDUSTRY

Our History from 1980 to Today

Our history shows our constant growth over time. The dream to go beyond the external quality of apples remained. And so, over time, we introduced cutting-edge technologies that have marked our history.

1981

Introduction of the Intel 8080 microprocessor for the numeric process control First introduction of a personal computer (Apple II) for the numeric process control

19811982

Development and introduction of infrared multiplex technology to create fine definition light grids

1982

1983

Integration of all control components such as microprocessors, memory, video, and keyboard control drives on the single-board industrial computer MiCROVIC

1983

1984

Video Interface Controller

1984

1985

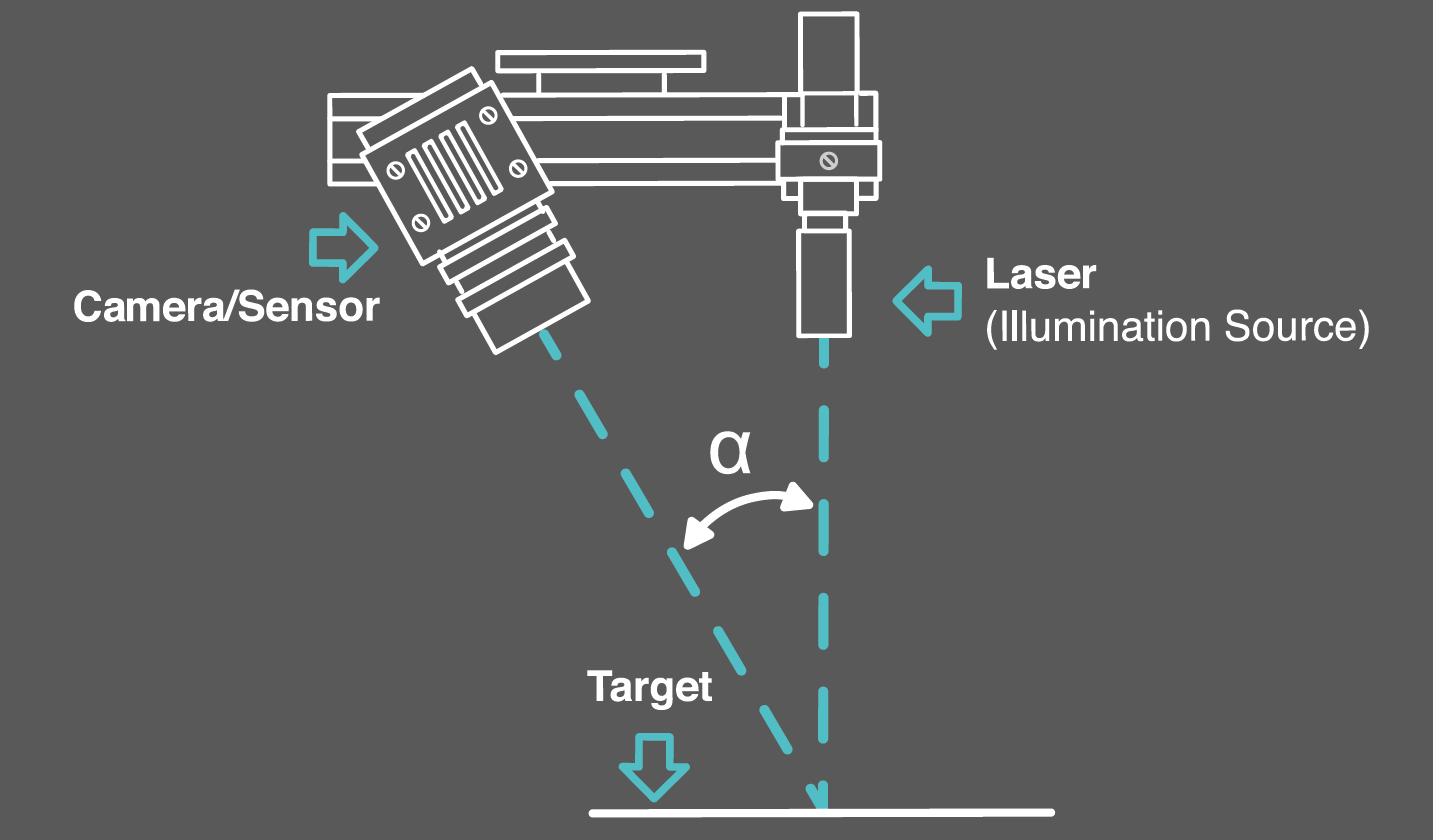

Introduction of the world's first laser light triangulation technique for 3D reconstruction of products'

surface

1989

Introduction of the graphic user interface and the mouse (Atari)

19891990

Development of real-time software driver units for automation on PCs

19901992

Development of a digital image processor based on parallel computing

19921994

Development of the first scanner for detection of defects

19941995

Implementation of X-ray technology for image processing support

1995

1997

Development and introduction of the laser scattering effect to recognize products’ defects

19971999

Application of machine learning methods based on neural networks for image processing

1999

2001

First tests with X-ray computed tomography and development of a radioscopy scanner for product scanning

2001

2008

Official presentation of the first industrial high-speed Computed Tomograph for industrial use

2008

2009

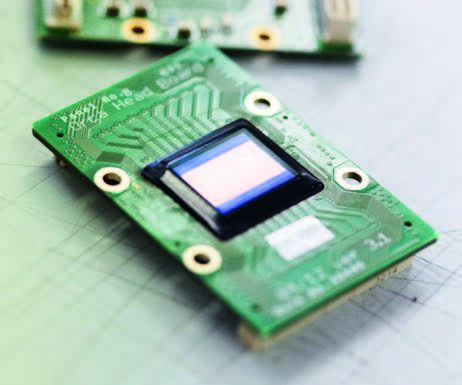

Development of a high-performance CMOS Sensor (Generation 1) for Biometic’s Crometic Camera

2009

2013

Introduction of the in-house developed digital Crometic camera for fruit processing applications with custom CMOS digital sensor providing images at ultra-high-speed with full HD resolution

New low power X-ray technology for efficient and safe operations

2016

Presentation of the newly designed Q Eye series with HD cameras as well as laser 3D and near-infrared (NIR) technology

2016

2018

Q Eye XP, BIOMETiC’s new internal fruit quality scanner featuring top-of-the-range- X-ray inspection for grading and packaging lines, is awarded the Interpoma Technology Award in the "Post Harvest" category

2018

2019

Official presentation of Mito, the first in-line 3D X-ray inspection system for food safety and quality inspection

Implementation of artificial intelligence and deep learning in all quality scanning solutions

2020

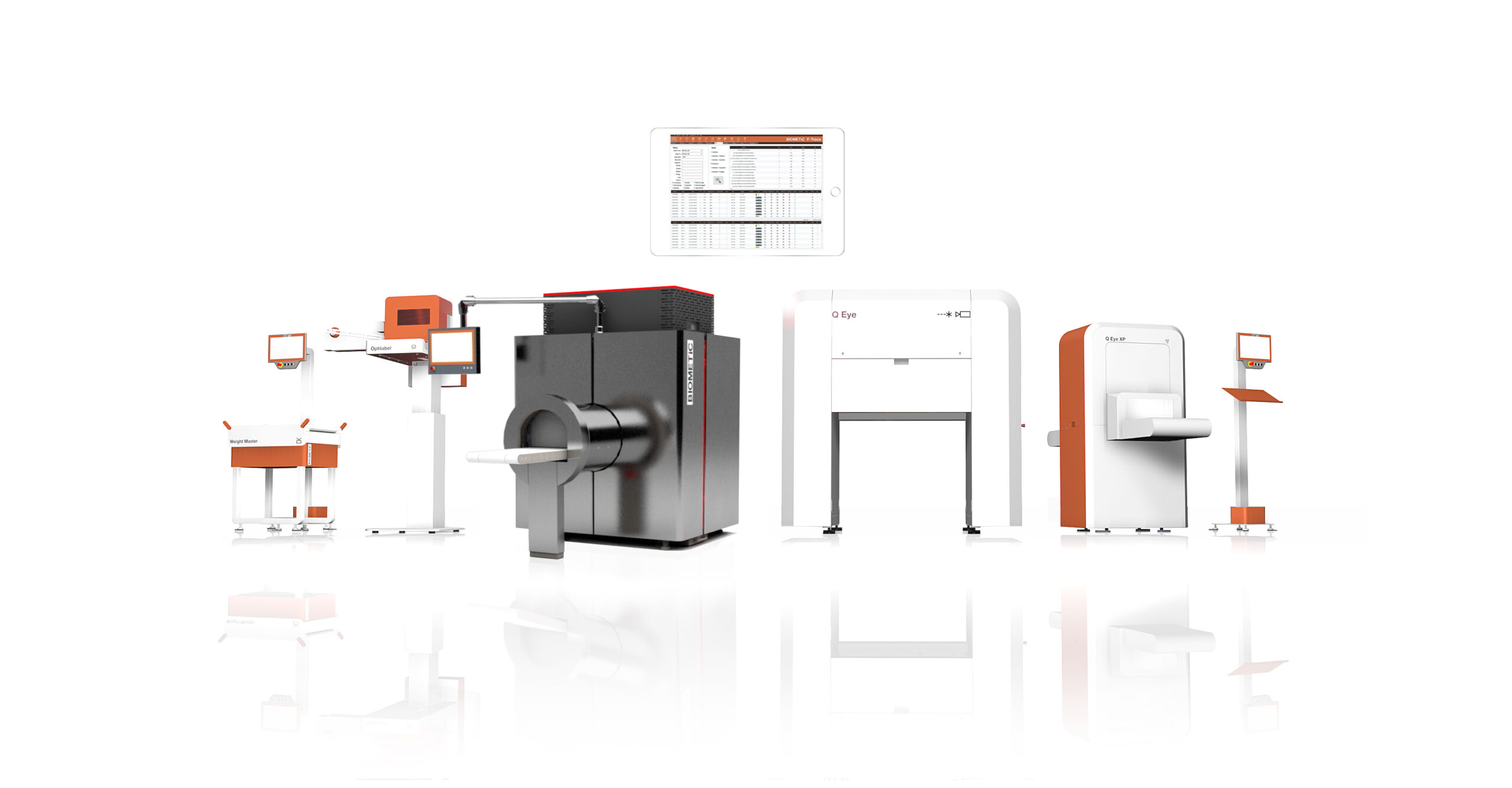

Introduction of the hyperspectral camera for fruit and vegetable quality inspectionPresentation of BIOMETiC’s new product design, where the orange color represents the sun and ripe fruits, and the white color stands for hygiene and cleanliness

2020

2020

Introduction of the BIOMETiC Ai Platform for all scanning systems

2020

2021

Winning of the international iF Design Award for Q Eye, Q Eye XP, Optilabel, Weight Master, and Tally, BIOMETIC’s inspection solutions for the fruit and vegetable sector

2021

2021

BIOMETiC wins the prestigious ADI Design Index 2021 Award with Mito, the first and only 3D X-ray inspection system for the food industry.

2023

The new BIOMETiC Q Eye Smart secures its spot among the top 10 nominees for the prestigious Fruit Logistica Innovation Award.

2023

2023

BIOMETiC Mito wins the CibusTec Innovation Award by redefining and elevating the product's safety for the food industry.

2023

2024

Introduction of Q Eye Stereo, the Smart AI Planning Solution for Fruit Cooperatives' Efficiency

2024

2025

Introduction of the new Mito M model, an extension of the Mito range designed to inspect even the largest formats thanks to a 500 mm conveyor width.

2025The latest news

From our Blog

- Blog

- Blog

- Blog

- Blog

Do Not Hesitate to Contact Us

We are at your complete disposal. We would be happy to provide you with our know-how and free consulting services to select the best BIOMETiC solution for your food inspection and fruit sorting needs.

Contact us now, and let’s discuss how we can make your food products and fresh produce better and more secure than ever before.