Mito - 3D X-ray Inspection System for Food Safety and Quality

The Solution to ensure Complete Food Safety and Quality.

Mito, the only 3D X-ray food inspection system on the market

The Effective Solution for Safe Food of Highest Quality

People working in the complex food production chain know the need to ensure safe and high-quality products to prevent consumer risks. This is why food manufacturers incorporate an in-line inspection device in their production lines.

What sets BIOMETiC Mito apart is its unique 3D X-ray food inspection technology with Artificial Intelligence – A single solution to verify the safety and quality characteristics of food products in real time, customizable according to the company’s production and inspection needs.

X-ray food inspection with 3D technology by Biometic

The Difference between a Conventional X-ray Device and Mito

A metal detector does not detect non-metallic contaminants. And a conventional 2D X-ray device does not guarantee sufficient reliability and accuracy in detecting foreign bodies at an unfavorable angle to the X-ray source.

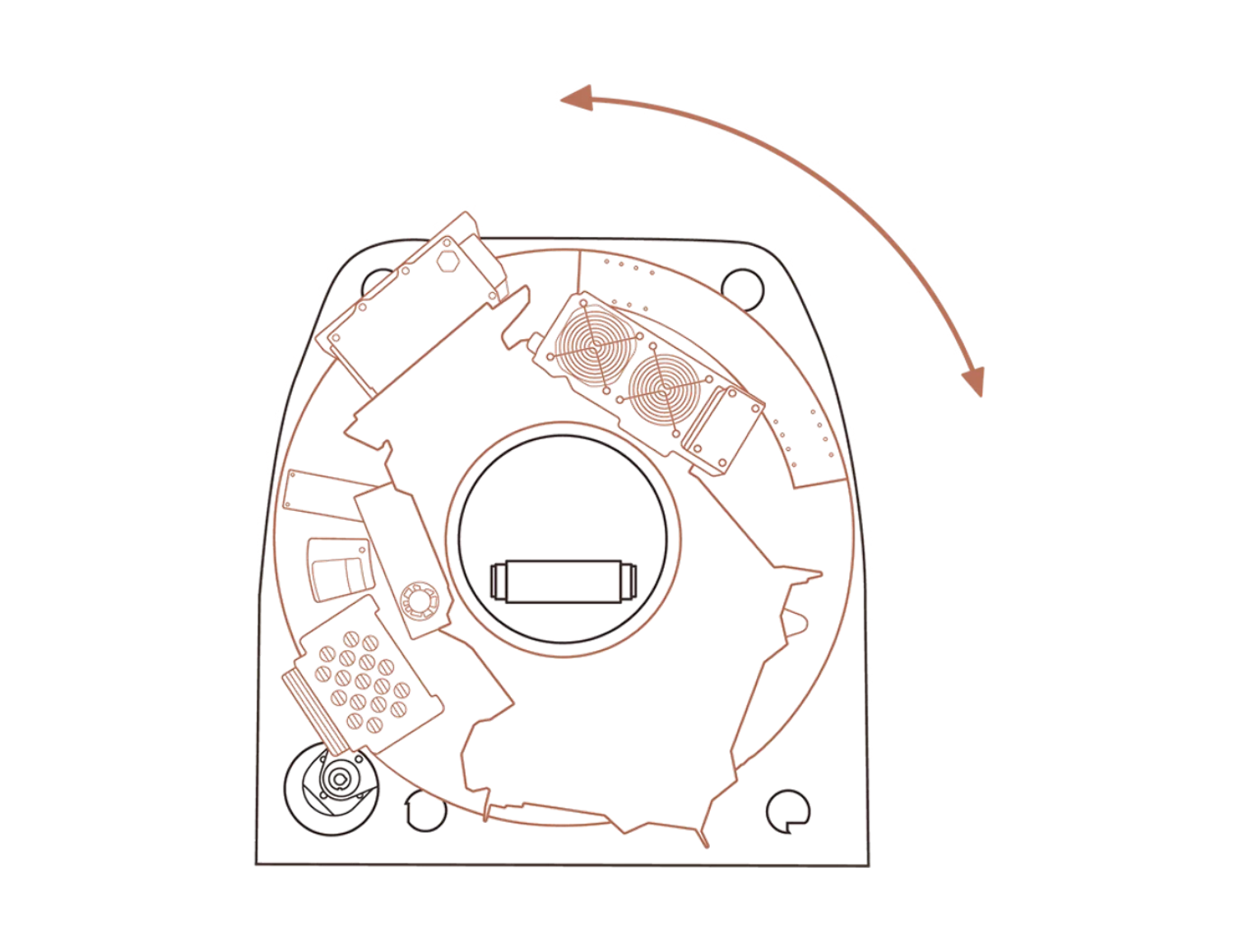

Mito is the first and only X-ray inspection system with 3D reconstruction technology on the market – a computed tomograph that scans food in-line in real-time. It captures and recreates in detail the shape, internal and external quality and safety characteristics, and packaging of your products.

Mito’s patented Computed Tomography technology offers significant advantages. These include fewer errors and waste, avoiding financial losses and complaints, and protecting the health of your consumers and your brand reputation.

We needed a more advanced technology than conventional X-rays. With Mito, we can now efficiently detect glass fragments inside jam multipacks.

3D X-ray inspection system for the food industry

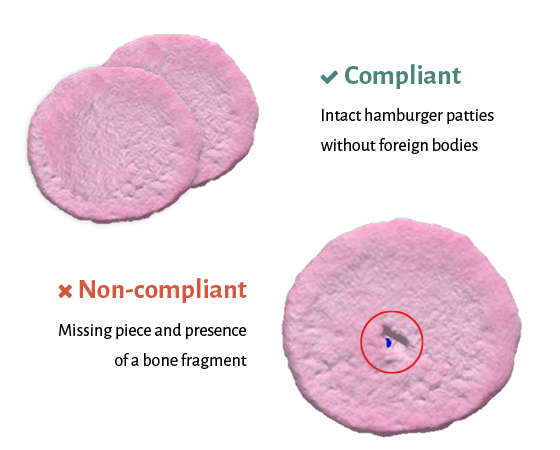

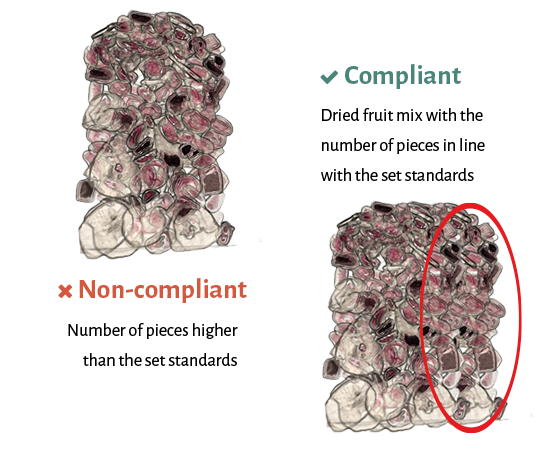

Possible Scan Results

Developed from over 40 years of experience in real-time inspection systems, Mito is specifically designed for the food industry and its needs – from protecting brand reputation to eliminating waste and optimizing production processes.

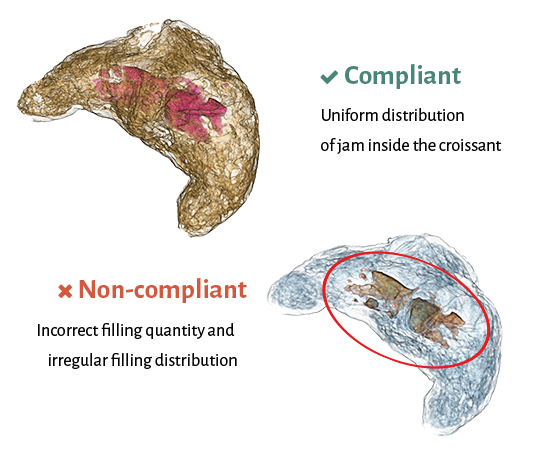

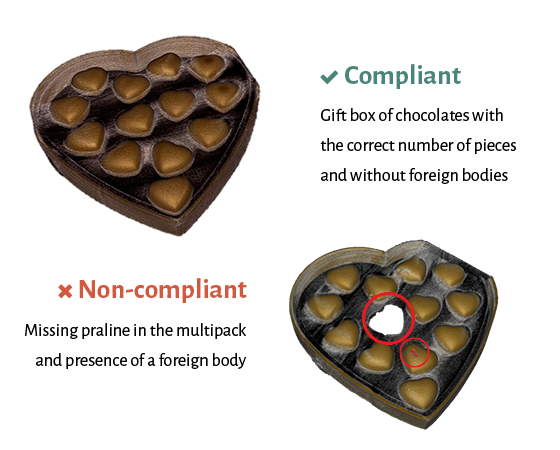

Here are just some examples of problems Mito has solved for different food industries:

- Bakery: Controlling the dosage and balanced distribution of ingredients to ensure a uniform product

- Cannery: Detection of glass-in-glass fragments, even in multipacks

- Cheese and Dairy: Recognition of foreign bodies and quality characteristics of different nature

- Sweets and Confectionery: Verification of the number of products by counting individual products within a package

- Meat and Fish: Detection of bone fragments

- Frozen Products and Ready Meals: Ejection of defective, damaged, or deformed products from the production line

- Snacks: Control of product dosage to avoid waste and ensure a premium product

- ...

Food control and inspection at 360 degrees for quality in the smallest details

BIOMETiC Mito Models for the Food Industry

Each food, like each sector of the food industry, has its own specific characteristics. That’s why the real added value of Mito is the fact that it is versatile and customizable to your production needs. With Mito’s powerful Computed Tomography, a unique combination of full 3D reconstruction and X-ray technology, food manufacturers can perform scanning and processing at very high speed and high definition detecting so any foreign bodies or food quality defects.

Discover how you can optimize your production processes today. Explore our range of Mito models to find the for your specific food safety and inspection needs.

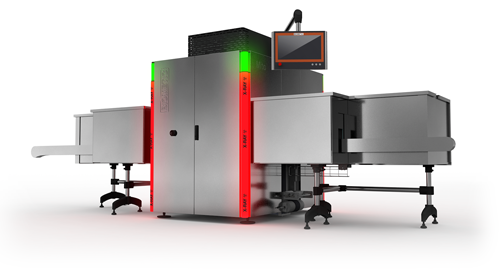

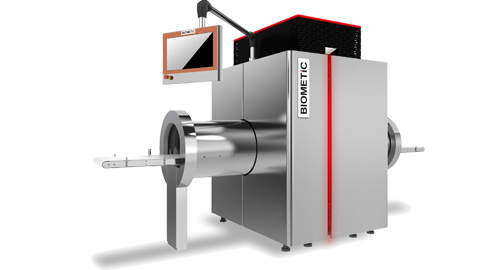

Mito C

- Computed Tomography (Full 3D Reconstruction & X-ray)

- Field of View: 250 mm

- Glass Jars, Glass Bottles, and Cans

- Food Safety (glass-in-glass, metals, plastics, …)

- Food Quality (fill level, jar seal, presence of vacuum, …)

- Production Processes Optimization

Mito M

- Computed Tomography (3D & X-ray)

- Field of View: 250 or 500 mm

- Multipacks and Generic Packagings

- Food Safety (metals, plastics, dough clumps, …)

- Food Quality (product's dimension and geometry, alveolation, product number in package, …)

- Production Processes Optimization

Mito B

- Computed Tomography (3D & X-ray)

- Field of View: 250 mm

- Bulk Products

- Food Safety (kernel fragments, stones, metals, …)

- Food Quality (integrity of product, shape, …)

- Production Processes Optimization

The best solution for in-line product inspection

Why our Customers choose Mito

We know that every industry and every company is unique and has different needs. For this reason, BIOMETiC’s real added value lies in adapting solutions to your specific inspection needs as a food manufacturer with multiple possibilities for food safety and quality inspections.

That’s why our customers have come to rely on Mito’s technology:

Increases product safety and quality

Compared to a conventional X-ray inspection solution, Mito’s significant advantage is that it provides stricter food safety and quality controls with fewer errors and waste by adapting mathematical algorithms based on the scanned product. It evaluates punctual density, not just average density, identifying defective, damaged, or deformed packages and products.

Adaptable to the products and the needs of the manufacturer

Mito grows with the needs of the company. It can be adapted to the products to be analyzed and your inspection needs as a food manufacturer.

Ensures significant savings

With Mito, you can calculate the exact quantities of raw materials to be used to optimize savings. As long as the right amount of product in a package and/or processing materials (such as the amount of filling in a croissant or the filling level of yogurt) is ensured in the production process, this translates into significant savings.

Protects brand reputation and optimizes production

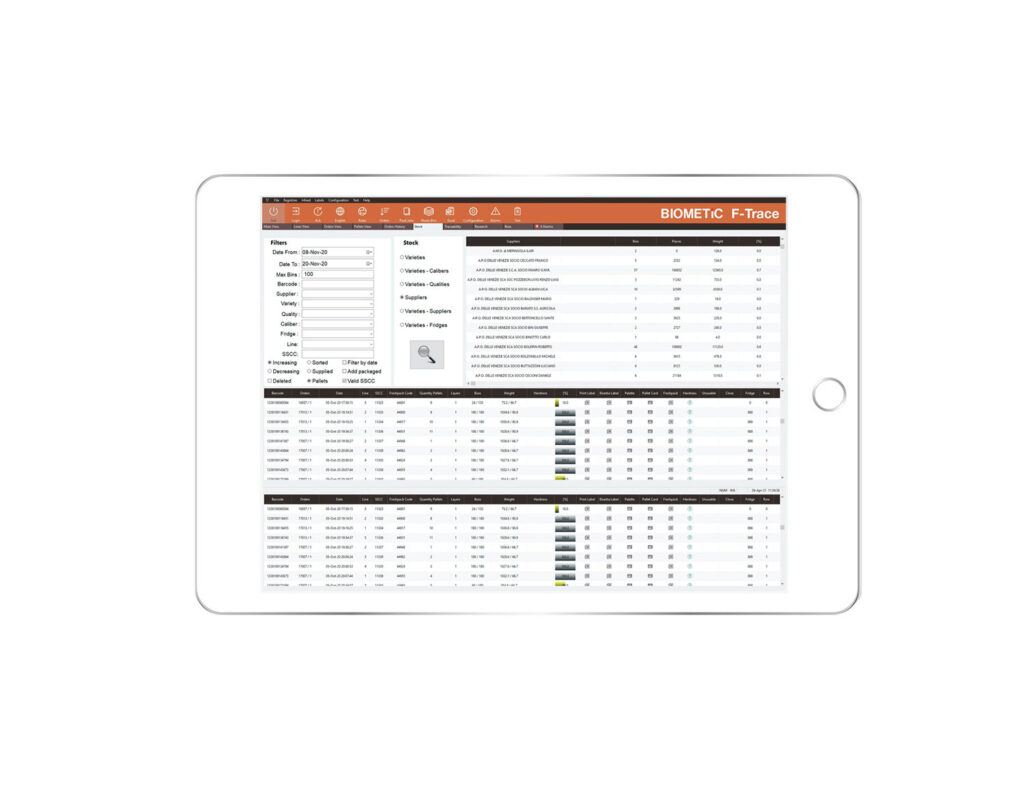

Mito can achieve these results as a single system. But by integrating it with the comprehensive food traceability solution F-Trace, the manufacturer can optimize the entire production flow and achieve maximum production efficiency across the whole line.

Verifies food with high-resolution images in total safety

To obtain better images, Mito uses a more powerful X-ray source than conventional X-ray inspection systems. Still, the radiation to which an operator is exposed, even if they were working 8 hours a day in close contact with Mito, is below the international limit for annual radiation exposure set at 1 mSv per year (mSv/y) by the International Commission on Radiological Protection (ICRP).

Simple and intuitive to use

Mito does not require calibration. It is easily integrated into any production line and has a user-friendly interface that makes its operation faster and more intuitive for the operator. Training is given when the machine is installed. In case, later on, training is needed for other operators, an extra training package on Mito can be added at any time.

It can be used in any industrial production line

Mito can be installed and operated in an existing industrial food production line. It is equipped with an internal sealed shielding for X-rays that guarantees total safety in the use of the system by the operators.

In-line food inspection and control with innovative technologies

BIOMETiC Products integrable into your Production Line

Do Not Hesitate to Contact Us

We are at your complete disposal. We would be happy to provide you with our know-how and free consulting services to select the best BIOMETiC solution for your food inspection and fruit sorting needs.

Contact us now, and let’s discuss how we can make your food products and fresh produce better and more secure than ever before.