Process Optimization Solutions: Technology to Optimize Your Food and Fruit Production Processes

Discover BIOMETiC’s Process Optimization Solutions for Food and Fruit. We can help you manage your Production Process Automatically and ensure Maximum Food Traceability.

Home » Production Process Optimization

Food, Fruit, and Vegetable Traceability

Process Optimization Solutions to Help You Ensure Maximum Food Traceability

Consumers want accurate information about products to make an informed and transparent choice when it comes to food. As a food manufacturer or producer, you want to be sure that you can reconstruct the entire process of the food and ensure healthy and safe products for your consumers.

This is why another important aspect of ensuring maximum safety and quality of food is optimizing the production process: So that in case of unsafe food batches, you can promptly withdraw from the market those at risk.

By integrating BIOMETiC’s smart optimization solutions into your line, you can now protect both your consumer’s health and your brand’s reputation. All this while optimizing your production processes and ensuring maximum food traceability.

Solutions for Production Process Optimization

Total quality control across every stage

Q EYE STEREO IN YOUR PRODUCTION LINE

ADVANCED STORAGE AND RETRIEVAL WITH FULL TRACEABILITY

Q Eye Stereo

Q Eye Stereo is specifically designed to streamline and elevate the management of fruits from the initial harvest stage to long-term storage. This new technology empowers fruit cooperatives to ensure consistent quality and optimize operations for a smoother, more efficient process.

When producers deliver their harvest to the cooperative, Q Eye Stereo steps in to perform a critical task. Leveraging stereoscopic vision and artificial intelligence, Q Eye Stereo measures the diameter of fruits in the uppermost layer of each crate. This innovative approach allows cooperatives to estimate diameter distribution across the entire shipment—quickly and precisely. This data is invaluable, helping to organize storage efficiently and enabling each producer to assess their produce’s quality and classification accurately.

- BIOMETiC Ai powered stereoscopy vision technology

- Integrated cold storage traceability system

- Automated storage and retrieval optimization

- Customizable and scalable for cooperative needs

Solutions for Production Process Optimization

Sorting and Traceability

TALLY IN YOUR PRODUCTION LINE

Control and Optimization of Fruit and Vegetable Sorting

Tally

Tally is a single solution that allows you to control and manage your orders as well as automate the selection and grading line.

It continuously collects and evaluates each fruit’s information (weight, size, volume, shape, and color) acquired from the optical sorter Q Eye Smart. In this way, Tally controls the processes and manages multiple sorting lines, output, and packing benches.

Tally works on any sorting machine and manages production in real-time according to your company’s needs. Besides, you have mobile access to the software for production control at your fingertips with the T Pad tablet device.

- Continuous optimization of quality, weight, and quantity of fruit and vegetables

- Management of multiple sorting, output, and packaging lines

- Processing and synchronizing incoming order data

Software for complete Food Traceability and Re-traceability

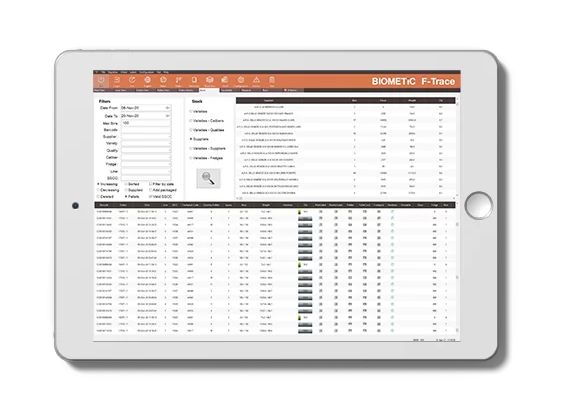

F Trace

F Trace is a complete solution that can be integrated into all production lines. It optimizes your processes, providing real-time data of the different processing phases, from supply and processing times to the shipment of your products.

By interacting with other machines in your production line, F Trace allows you to manage your production processes.

A single flexible and customizable tool that allows you to control and manage your production at 360 degrees in real-time.

- Ensures a complete overview of your food at all stages of production

- Interacts with all machines and technologies in your line

- Monitors, evaluates, and optimizes production processes in real-time

F Trace in your production line

Do Not Hesitate to Contact Us

We are at your complete disposal. We would be happy to provide you with our know-how and free consulting services to select the best BIOMETiC solution for your food inspection and fruit sorting needs.

Contact us now, and let’s discuss how we can make your food products and fresh produce better and more secure than ever before.