3D X-Ray Inspection Solutions for Food Safety and Brand Protection

BIOMETiC’s 3D X-ray Inspection Solutions help you ensure Safe Products to Consumers. Protect your Brand Reputation with our Food Safety Solutions.

Home » Food Safety and Brand Protection

Food Safety and Consumer Protection

Ensure Food Safety with 3D X-ray Food Inspection

In response to consumers’ growing need for food safety and health protection, numerous inspection systems on the market analyze food products for certain foreign bodies or quality defects.

Compared to conventional X-ray inspection solutions, BIOMETiC’s three-dimensional X-ray inspection and optimization systems can detect defective products and multiple types of hazardous physical contaminants, even glass-in-glass.

Monitor your production dynamically in real-time to ensure food safety and suitability. In this way, contaminated products are ejected from the production line before they reach the consumer’s table.

Detect and prevent foreign bodies and contaminants in food

BIOMETiC Products for Food Safety

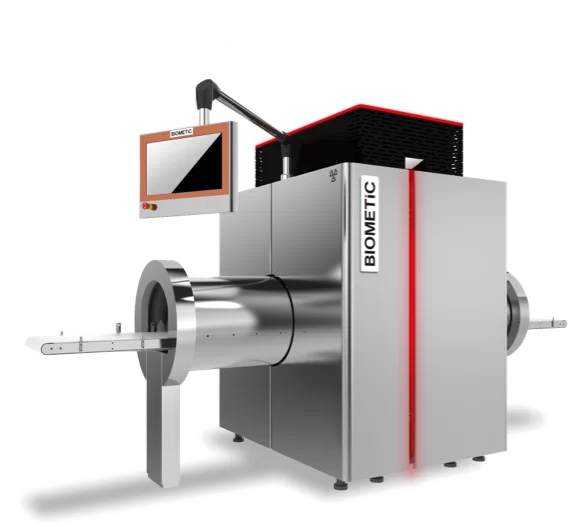

Mito in your production line

3D X-RAY INSPECTION SYSTEM FOR FOOD SAFETY AND QUALITY

Mito

Mito is the first and only in-line 3D X-ray food inspection system for the food industry.

As a complete solution for food safety and quality, it guarantees food and consumer safety, protection of brand reputation, and quality and process optimization.

Compared to conventional metal detectors and X-ray inspection systems with 2D technology, Mito applies non-destructive 3D in-line scanning technology combined with artificial intelligence, resulting in more accurate safety and quality checks with fewer errors and waste.

- 3D X-ray scanning and reconstruction inside and outside the product

- Integration into existing lines

- Detection of foreign bodies regardless of their position, even in pre-packaged products

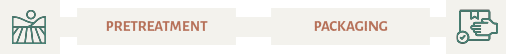

Software for complete Food Traceability and Re-traceability

F Trace

The software F Trace is a complete solution that can be integrated into all production lines. It optimizes your processes, providing real-time data of the different processing phases, from supply and processing times to the shipment of your products.

By interacting with other machines in your production line, F Trace allows you to manage your production processes in real-time. A single flexible and customizable tool that allows you to control and manage your production at 360 degrees.

- Ensures a complete overview of your food at all stages of production

- Interacts with all machines and technologies in your line

- Monitors, evaluates, and optimizes production processes in real-time

F Trace in your production line

Q Eye XP in your production line

X-ray inspection system for final safety and quality checks

Q Eye XP

Q Eye XP is the only X-ray inspection system designed for packaging lines and large-scale retail trade for the final safety and internal quality control of your boxed fruit and vegetables.

Working with artificial intelligence, Q Eye XP analyzes and detects any internal defects in your products, such as rot, corkiness, or foreign bodies. In addition to determining the internal quality and checking the safety of your products, Q Eye XP weighs your fruit and vegetable boxes to ensure their perfect weight.

- Final quality and food safety checks before the product reaches the consumer

- Verification of internal quality and presence of foreign bodies

- Better and more sustainable production with less waste and complaints

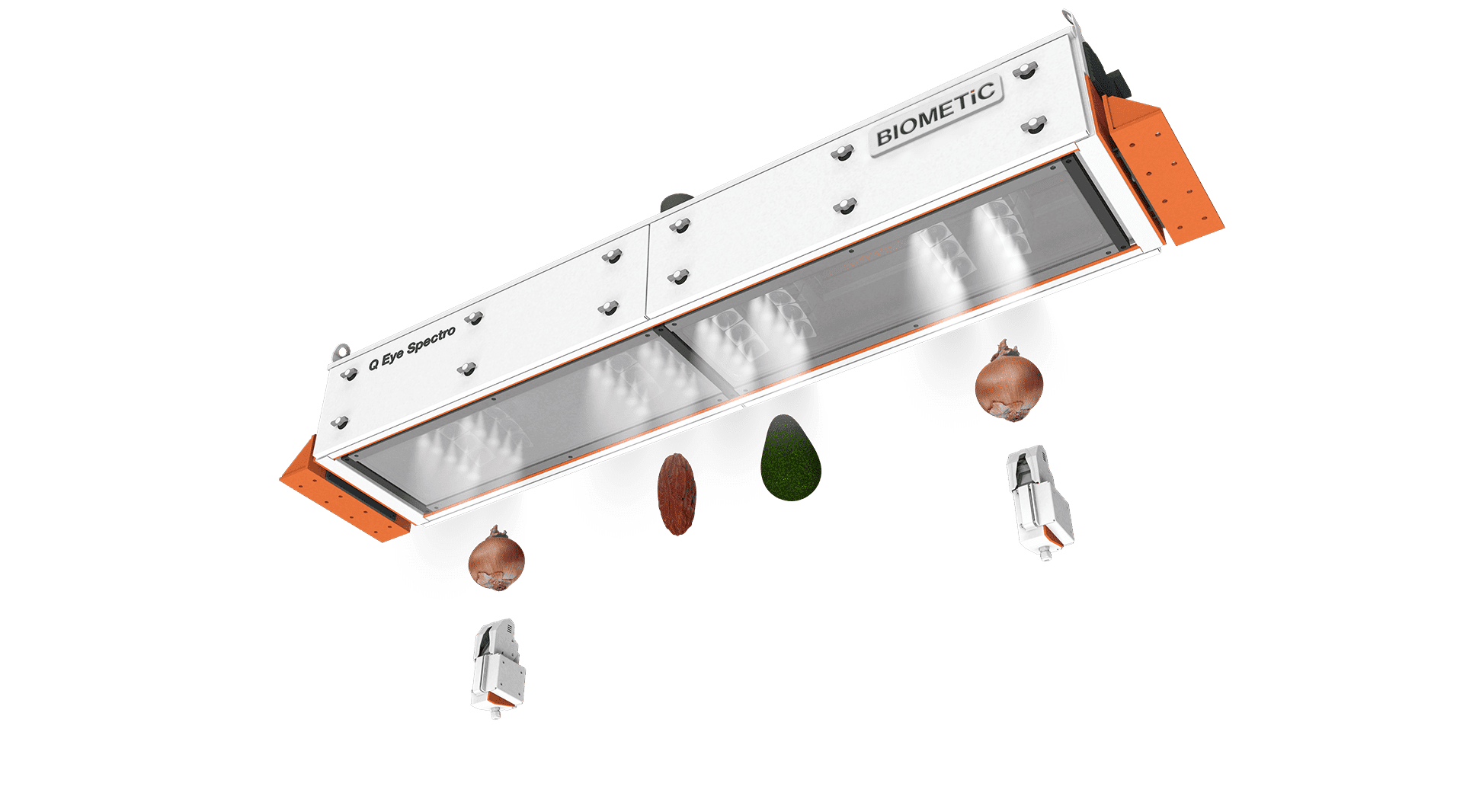

Internal Quality Scanner for Fruits and Vegetables

Q Eye Spectro

BIOMETiC Q Eye Spectro sets new standards for non-destructive internal quality scanning of fruits and vegetables. It guarantees superior precision, maximizes efficiency, and reduces waste and costs, with easy integration into both existing and new production lines.

- Advanced proprietary technologies for fast and precise internal quality control, with customized sorting through personalized quality classes

- Swift calibration following the seasonal produce evolution, optimizing sorting and minimizing waste

- Intuitive software to set quality parameters, manage results, and generate detailed statistical reports

Q Eye Spectro in your production line

OUR RECENT CASE STUDIES

Customer Success Stories

Do Not Hesitate to Contact Us

We are at your complete disposal. We would be happy to provide you with our know-how and free consulting services to select the best BIOMETiC solution for your food inspection and fruit sorting needs.

Contact us now, and let’s discuss how we can make your food products and fresh produce better and more secure than ever before.