HIGH-PRECISION APPLE SORTING WITH ARTIFICIAL INTELLIGENCE AND 3D TECHNOLOGY

How we help you meet your Fruit Quality Requirements

As for what concerns apple sorting, BIOMETiC has always been a step ahead in understanding apple packers’ needs when it comes to reliable and accurate defect detection. We have specialized in bringing innovative scanning technologies to the market that help minimize costs, automate sorting lines, and increase the efficiency of production lines.

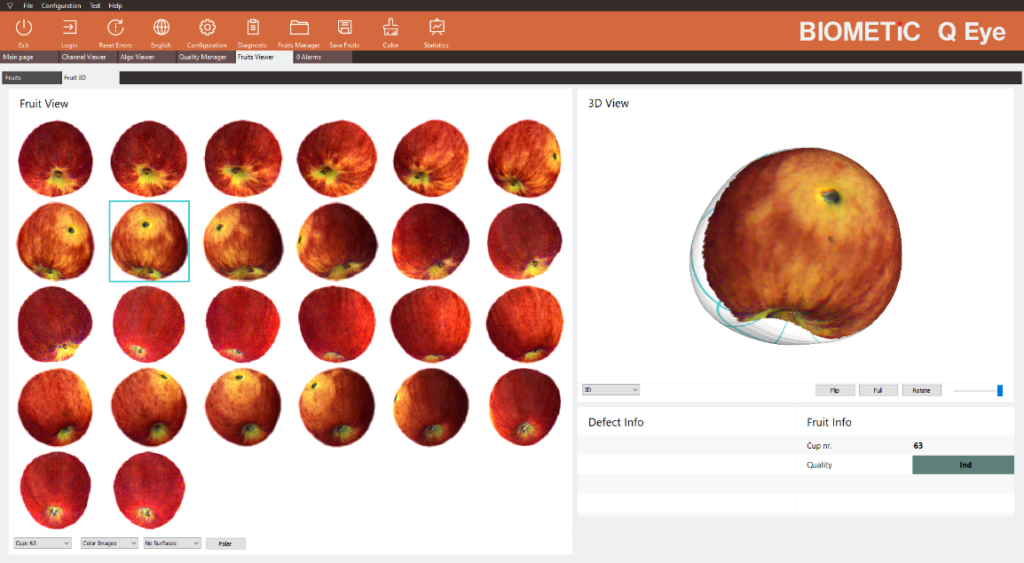

One of these quality control systems is Q Eye, the award-winning, intelligent optical sorter for the external quality analysis of apples. Q Eye technology has already convinced several customers worldwide that retrofit their existing sizers with our technology.

By integrating it directly into the sorting lines, Q Eye analyzes apples in real time with extremely high accuracy. Its real 3D in-line reconstruction and high-precision scanning of the products’ surface characteristics, color, size, and volume guarantee apple packers optimized sorting.

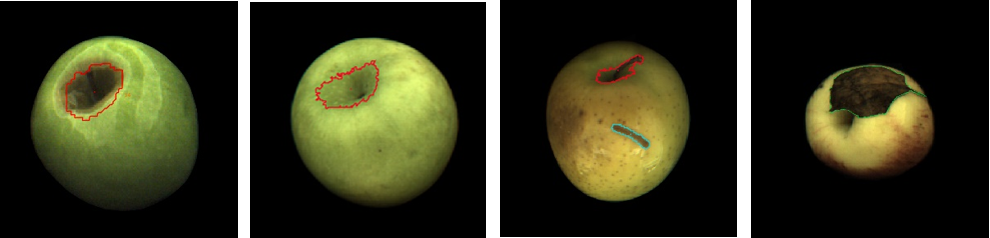

Combining its 3D reconstruction software with Artificial Intelligence networks enables Q Eye to perform even more precise quality controls and the detection of difficult defects. In this way, BIOMETiC real 3D reconstruction allows the packers to detect and determine each defect and its position to assign the fruits to the sorting exits accordingly.

Since the 3D reconstruction allows determining the defect position on the fruit, it is also possible to weigh the importance of the defect according to where it is located. For example, cracks around the apple stem are categorized in a lower quality class than cracks around the apple calyx. This is because the stem cavity is the first thing a final customer sees at the supermarket.

Adding to this, Q Eye‘s active rotation control algorithms measure how much the apple has rotated to avoid double-counting possible surface imperfections. Thanks to its user-friendly software interface, our customers’ operators can easily access the quality parameters. The operators can so easily customize the parameters and get production statistics for a complete overview of the sorting line.

About BIOMETiC

BIOMETiC emerges as the food spin-off of MiCROTEC, the technology leader in measurement systems and automated processes for the wood industry. Benefiting from over 40 years of MiCROTEC’s experience and know-how, we have adapted the technologies to develop in-line fruit and vegetable scanners and optimize processes.

BIOMETiC innovative in-line quality scanning solutions and systems are customizable. They can be adapted to the fruit and vegetable industry’s wide range of quality and sorting needs: from apples and citrus fruits to exotic fruits such as avocados and pomegranates.

Our technology and experience enable so innovative and sustainable quality scanning solutions, backed up by our 24/7 customer support and after-sales services.