Q Eye Smart - The Only Optical Sorter fully based on AI for Fruit and Vegetables

The optical sorter Q Eye Smart is the Unique Quality Scanner Fully based on Artificial Intelligence (BIOMETiC Ai) for Continuously Optimized High-Quality Sorting of Fruit and Vegetables. Book your free Online Demo now.

Q Eye Smart, the fastest and most accurate Optical Sorter

Ensure precisely selected and sorted Fruits and Vegetables

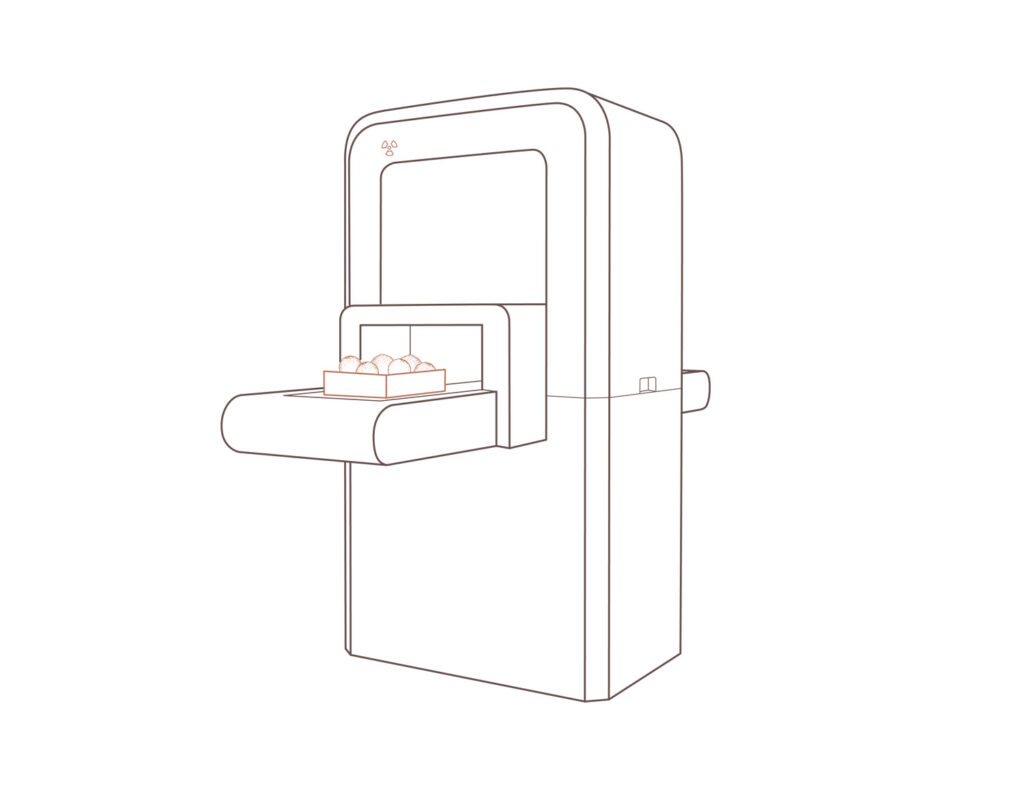

BIOMETiC’s optical sorter Q Eye Smart ensures the optimized sorting of fruits and vegetables and guarantees retailers and consumers fresh produce of high quality. It is fully based on artificial intelligence and equipped with rotation control.

Through its unique technology and ultra-high-precision rotation analysis, Q Eye Smart excludes multiple counting of surface defects. As a result, it avoids rejecting quality produce and therefore minimizes in-line waste.

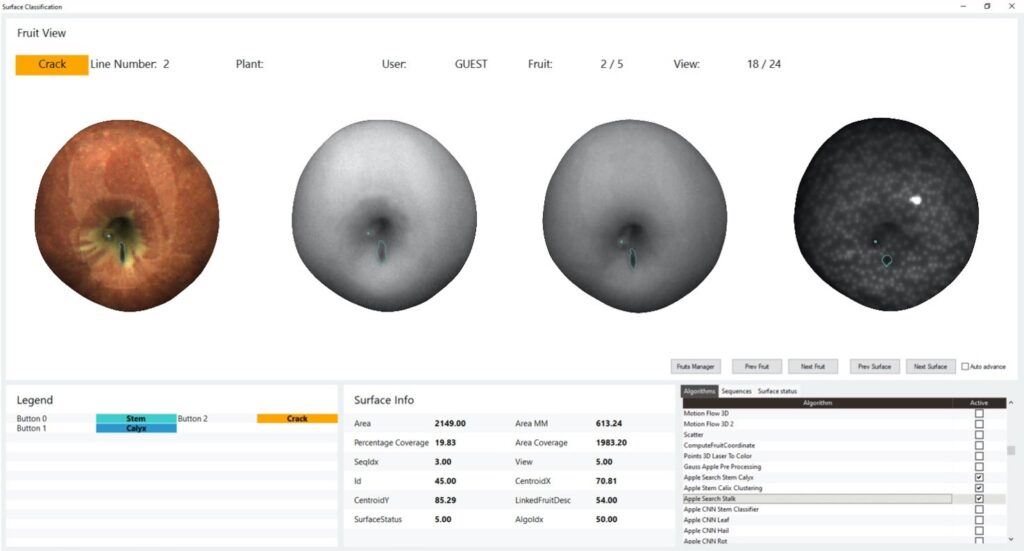

Fruit and Vegetable Sorting with AI and 3D technology

The Difference between a Conventional Optical Sorter and Q Eye Smart

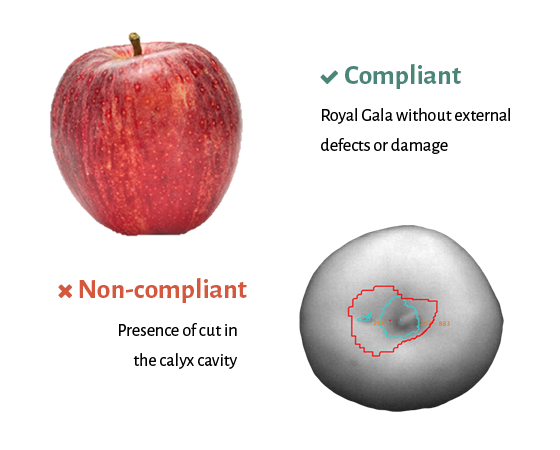

Compared to a conventional sorter, Q Eye Smart works with artificial intelligence, allowing continuous defect detection improvement. Its ultra-high-speed image processing detects even the smallest and most difficult external quality defects, such as cuts in the calyx area of apples.

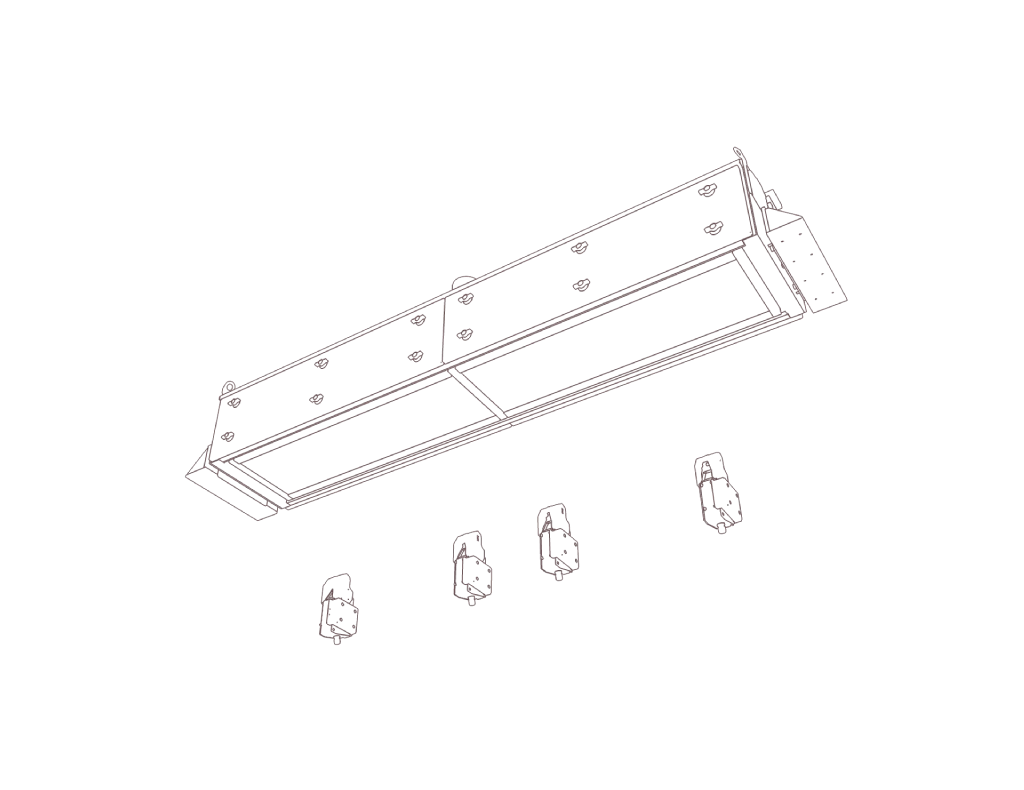

Through its high sorting speed, Q Eye Smart guarantees you first-class produce, grader independence, and easy retrofit installation on existing lines of packing houses.

As a result you can maximize yield, reduce waste, and avoid financial losses with BIOMETiC’s opitcal sorter.

Q Eye Smart, powered by BIOMETiC Ai, is the ultimate fruit scanning technology that guarantees us reliable, precise, and continuously optimized sorting.

MENACHEM SHOHAMOwner & Development Manager

3D Optical Sorter for Accurate Fruit and Vegetable Sorting

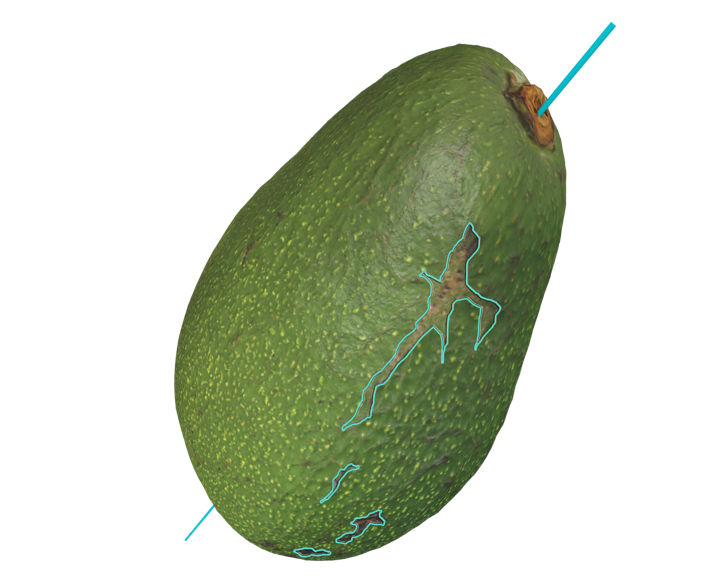

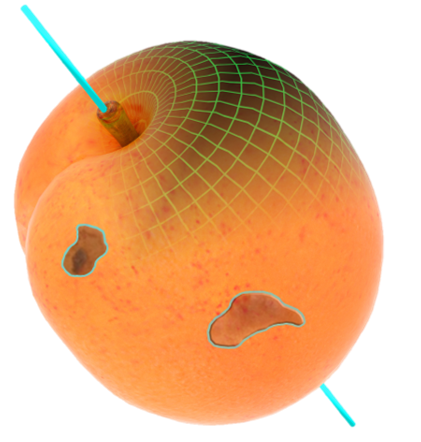

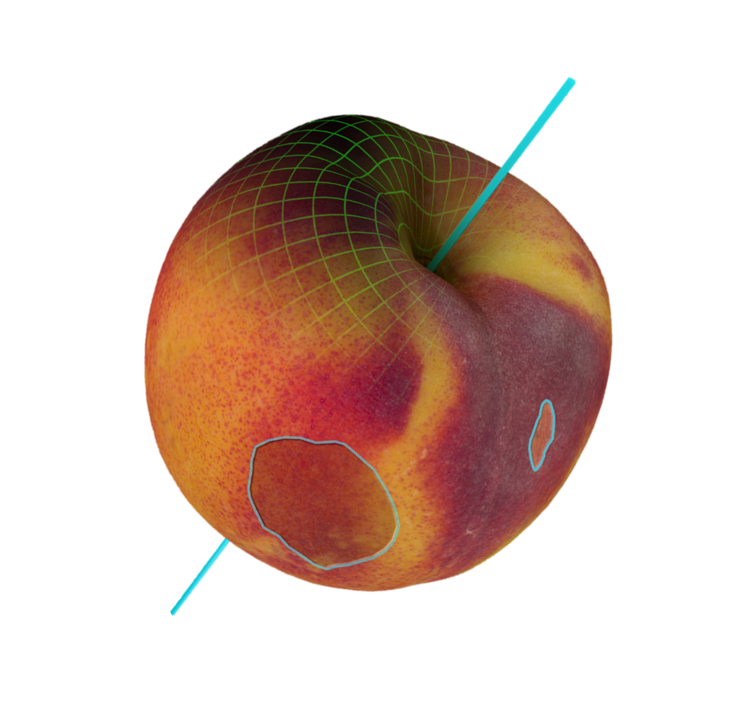

Application Examples

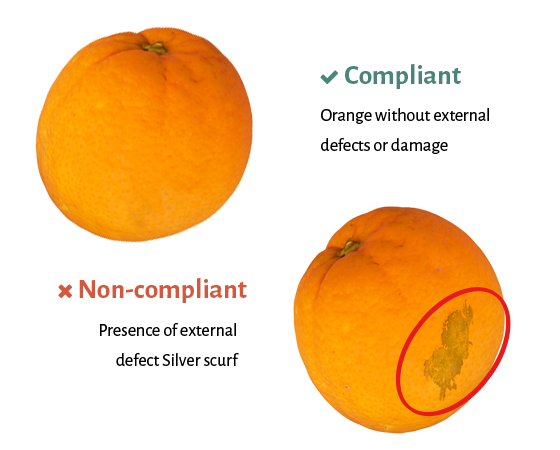

Like every company in the fruit and vegetable chain, every fruit and vegetable has specific characteristics. Therefore, the real added value of BIOMETiC Q Eye Smart is that it is versatile and customizable.

Q Eye Smart verifies and detects external quality defects of different types and varieties of fruit or vegetable. For this, it uses mathematical algorithms adaptable to the fruit to be scanned and the quality characteristics to be detected.

Furthermore, the packhouses scan their produce at high speed and definition thanks to its sophisticated, innovative analysis.

Q EYE SMART IN YOUR PRODUCTION LINE

Fast and accurate Sorting of your Fruits and Vegetables

Possible Scan Results

BIOMETiC’s experience and know-how now dates back over 40 years. Our technical know-how, combined with artificial intelligence (Ai) since 1999, has enabled us to implement BIOMETiC Ai, our artificial intelligence platform, into the Q Eye Smart sorter. Consequently, we have been able to solve numerous problems regarding the external quality of fruits and vegetables.

Listed below just some of the specific external quality defects and characteristics of fresh produce that Q Eye Smart can detect:

- Citrus Fruits: Naked Stem, Torn Stem, Stem Unclean, Calyx/Stem Ring, Defective Calyx, Silver Scurf, Stalk Short/Long, Rot, Rust, Creasing, Scratch Light, Scratch Dark, Cut/Punctures,…

- Avocados: Corkiness, Brown/Black Rubbing, Red/Yellow/Black Sunburn, Yellow Fruit, Ground Contact, Moth, Virus, Rot, Roden Bites, Hail, Deep Injury, Deformation,...

- Pomegranates: Dark and Black Spots, Color Variations, Russet and Rubbing, Cracks, Sunburn, External Rot, …

- Apples: Stem/Calyx Rot, Hail, Stem Crack, Stalk Puncture, Deep Injury, Russet, Bruise, Red Face, Rotten Dot, Holes, Scab, Bitter Pit, Dark Blemish, Alternaria,…

- Mangoes: Superficial Rubbing, Serious Rubbing, Color Variations, Deep Injuries, Soot And Parasites, Windrub, Rot, Moth, Shape Defect, Ground Contact, Sunburn, Rotten Dots,….

- Dates: Yellow Ring, Loose Skin, Length, Width, Diameter, Weight (if load cell is present), ...

- Onions: Single Crack, Half Skinned, Fully Skinned, Midly Stained, Heavy Stained, Pink Stain, Heavy Pink Stain, Light Damage, Heavy Damage, Misshaped, Sprouts, Dead Open, Root Disease, Rotten, Stones, Seeder, Potatoes, Hollow Pipe, Compression Bruise, Severe Dehydration,...

- ...

OUR RECENT CASE STUDIES

Customer Success Stories

The best Solution for in-line Fruit and Vegetable Sorting

Why our Customers choose Q Eye Smart

Born from BIOMETiC’s more than 40 years of experience in in-line inspection systems, Q Eye Smart is BIOMETiC’s intelligent optical sorter specifically designed for the fruit and vegetable packinghouses and their needs – from eliminating waste to ensuring the highest quality of fruit and vegetables.

Here’s why our customers have come to rely on Q Eye Smart :

Increases produce quality

Compared to a conventional optical sorter, the big advantage of Q Eye Smart is its artificial intelligence and non-destructive analysis, based on optical scattering. Through them, Q Eye Smart ensures tighter food quality control with fewer errors and waste. Its ultra-high-precise rotational analysis accurately evaluates fruits and vegetables, excluding multiple counting of surface defects.

Adaptable to produce and producer needs

Q Eye Smart grows with the needs of the company. It can be adapted to the type of fresh produce to be analyzed and to every need of the fruit and vegetable chain. This is why many companies, for whom it is even more important to ensure top quality produce to the international market, have chosen to include Q Eye Smart in their lines. From South Tyrol, with its countless varieties of apples, to Sicily, the land of citrus fruits, to Israel with its selection of top-quality exotic fruits.

Ensures significant savings

With Q Eye Smart, you can analyze, sort, and select fruits and vegetables based on external quality, shape, color, volume, and weight criterias to deliver high-quality produce to retailers and your consumers. Integratable across multiple lines, the Q Eye Smart intelligent sorter examines fruit and vegetables by combining electronic sensors, advanced image processing, and artificial intelligence.

Protects brand reputation and optimizes production

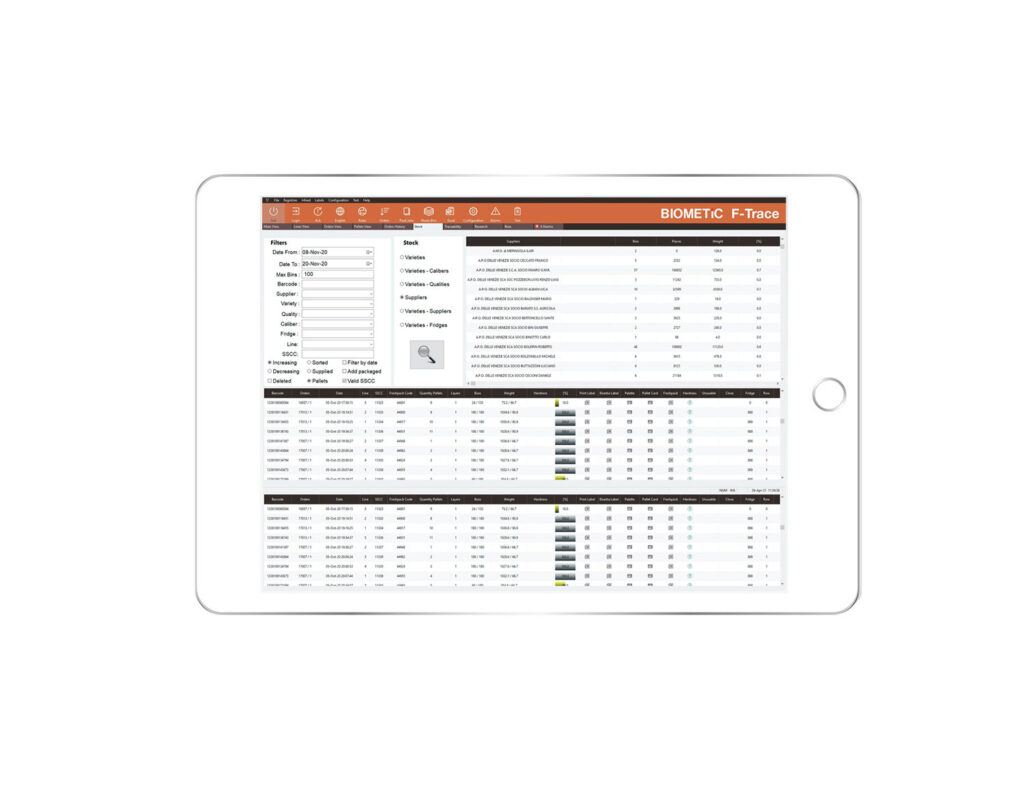

Q Eye Smart can achieve these results as a single system. But by integrating it with the complete traceability solution F-Trace, the company can optimize the entire production flow and achieve maximum production efficiency across the whole line.

Sorts fruit and vegetables and recreates high-resolution 3D models

To obtain better images, Q Eye Smart uses artificial intelligence, proprietary electronic sensors, and scatter technology – a non-destructive optical scatter-based technology that meticulously scans the surface of fruit and vegetables. Its ultra-high-speed image processing, with a resolution of up to 0.1 mm/pixel, ensures that even the smallest and most difficult external quality defects can be detected.

Simple and intuitive to use

Q Eye Smart requires minimum calibration. It is easily integrated into any production line and has a user-friendly interface that makes its operation faster and more intuitive for the operator. Training is given when the machine is installed. In case, later on, training is needed for other operators, an extra training package on Q Eye Smart can be added at any time.

It can be used in any industrial production line

Q Eye Smart can be easily installed and commissioned in existing sorting lines of the fruit and vegetable industry companies. With its high sorting speed of up to 20 fruits per second per line, independence from the grader, and easy retrofit installation on existing lines, Q Eye Smart guarantees reliable and effective sorting of your fruits and vegetables.

In-line food inspection and control with innovative technologies

BIOMETiC Products integrable into your Production Line

Do Not Hesitate to Contact Us

We are at your complete disposal. We would be happy to provide you with our know-how and free consulting services to select the best BIOMETiC solution for your food inspection and fruit sorting needs.

Contact us now, and let’s discuss how we can make your food products and fresh produce better and more secure than ever before.