Artificial Intelligence as Key Tool for Optimized Citrus Sorting

BIOMETiC’s innovative quality scanning solutions for citrus sorting are powered by Artificial Intelligence (AI). They enable continuous improvement of the detection of difficult defects that cannot be found using normal algorithms.

AI is in fact the key tool for producers to increase stability, reliability, and accuracy when sorting their citrus fruits.

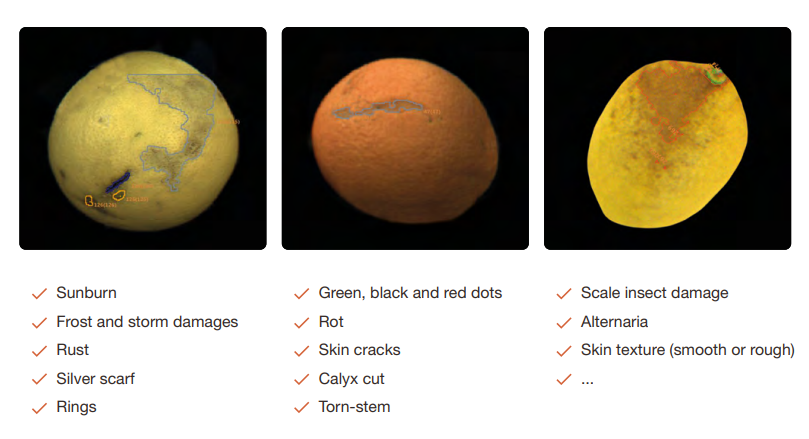

Some of the defects you can detect with our quality scanners include:

- Rot (even small dots of “clear” rot)

- Punctures

- Torn-stem ends

- Calyx damages

- Cracks

- Black damages

- Presence of labels

Unique 3D Reconstruction for Top-Quality Produce

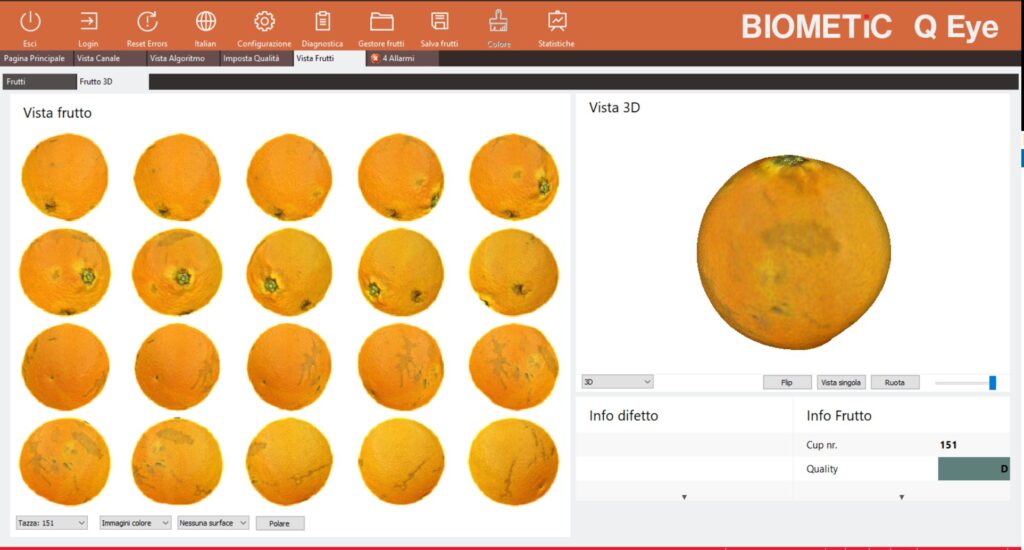

The real 3D reconstruction – BIOMETiC patented technology – enables producers to precisely locate defects on the fruit surface, giving them exact coordinates. Consequently, each defect is counted only once so as to guarantee precise and optimized fruit sorting. The 3D reconstruction allows you so to name each defect and optimize its sorting.

Unlike other technologies, BIOMETiC’s unique 3D reconstruction and AI platform allow you to consider the fruits’ stem and calyx and the area around them (and thus not ignore them from the calculation).

As an example, by implementing the BIOMETiC quality scanner in your production lines, you can detect even torn stems, the presence of long stalks, and any cracks around the stem. By doing so, you can ensure top-quality fruits when exporting.

Since the 3D reconstruction allows determining the position of the defect on the fruit (with spatial coordinates), as a producer you can also weigh the severity of the defect according to where it is. For example, cracks around the stem are categorized in a lower quality class (they are more important since it is the part the consumer sees when buying at the supermarket) than cracks in the bottom part of the fruit.

Additionally, the rotation control technology allows you to establish how much the fruits have rotated while inspected by BIOMETiC cameras. Consequently, if the fruit has not rotated sufficiently, you may dedicate a separate sorting exit or recirculate the fruit to scan it again.

Intelligent Optical Sorting for Maximized Yield and Produce Quality

However, BIOMETiC technologies can go even further.

An example is implemented in Shoham Ltd.’s facilities. They decided to go forward with BIOMETiC’s technology by replacing all the old scanners present in the packinghouse with BIOMETiC scanners. This solution has allowed the producer to increase the automation in its packinghouses and avoid any manual sorting.

Q Eye is BIOMETiC’s intelligent optical sorter that ensures the optimized sorting of fruits and vegetables. It classifies citrus precisely by their external quality, shape, color, volume, and weight criteria.

As a result, Q Eye enables packinghouses to maximize yield, reduce waste, and meet their fruit quality requirements.